1. All kinds of structural bonding; 2. Glass\aluminum curtain wall,lighting awning and other metal building bonding. 3. Hollow glass structural bonding and sealing;

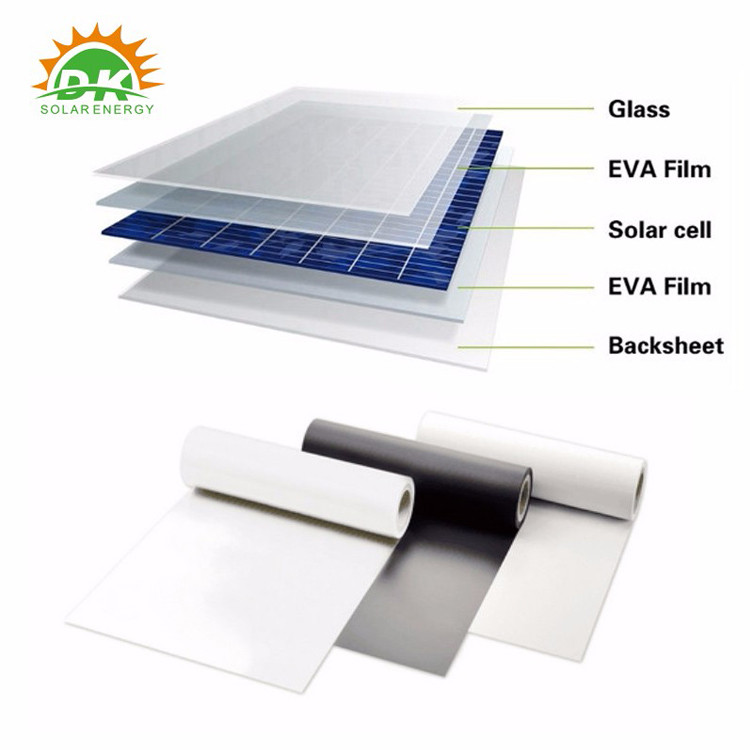

1.Why choose XinDongke Solar? We established the business department and a warehouse which covers 6660 square meters in Fuyang, Zhejiang. Advanced technology, professional manufacture, and excellent quality. 100% A grade cells with ±3% power tolerance range. High module conversion efficiency, low module price Anti-reflective and high viscous EVA High light transmission Anti-reflective glass 10-12 years product warranty, 25 years limited power warranty. Strong productive ability and quick delivery. 2.What are your products lead time ? 10-15days fast delivery. 3.Do you have some cerfiticates ? Yes, we have ISO 9001, TUV nord for our Solar Glass, EVA film, Silicone sealant etc. 4.How can I get a sample for quality testing? We can provide some free small size samples for customers to make a testing. Sample shipping fees should be paid by customers. kindly notes. 5.What kind of solar glass can we choose? 1) Thickness available: 2.0/2.5/2.8/3.2/4.0/5.0mm solar glass for solar panels. 2) The glass used for BIPV / Greenhouse / Mirror etc. can be custom according to your request.

Product Overview The assembling of the photovoltaic module frame and laminated parts after lamination requiresclose coordination, strong connection, good sealability, and prevention of destructive liquidsand gases from entering. Connection boxes and backboards need to be well bonded, even iflong-term use under local stress page patching off. This product is a neutral curable siliconesealant specially designed and developed for the bonding requirements of solar photovoltaicmodule aluminium frame and junction box. It has excellent bonding performance, excellent agingresistance, and can effectively prevent the gas or liquid infiltration which has destructive effect.

Product Overview The assembling of the photovoltaic module frame and laminated parts after lamination requiresclose coordination, strong connection, good sealability, and prevention of destructive liquidsand gases from entering. Connection boxes and backboards need to be well bonded, even iflong-term use under local stress page patching off. This product is a neutral curable siliconesealant specially designed and developed for the bonding requirements of solar photovoltaicmodule aluminium frame and junction box. It has excellent bonding performance, excellent agingresistance, and can effectively prevent the gas or liquid infiltration which has destructive effect.

| Color | White/black |

| Viscosity, cps | Non-slump |

| Solidfication type | Single component alkone wo |

| Density, g/cm3 | 1.39 |

| Tack -Free Time (min) | 5~20 |

| Durometer hardness | 40~55 |

| Tensile strength(MPa) | ≥2.0 |

| Elongation at Break(%) | ≥300 |

| Volume resisitivity(Ω.cm) | 1×1014 |

| Disruptive strength,KV/mm | ≥17 |

| Working temp(℃) | -60~260 |